MISSION STATEMENT

“We will design solutions, in consultation with our clients, in a joyous environment for our people.”

COMPANY PROFILE

M/s. VeeraDutta Engineering Pvt.Ltd., company formed under legal framework of GOVERNMENT OF INDIA - MINISTRY OF CORPORATE AFFAIRS, for providing Detail Engineering and Trouble Shooting Solutions in the field of Piping, Process, Equipment, Mechanical, Electrical and Instrumentation Engineering. Additionally company will be provide technical training to experienced professionals and fresh graduates on API-570 certification training, ASME Codes, Piping Design, Valves, Pipe Flexibility Analysis etc.

M/s. VeeraDutta Engg. Pvt.Ltd.is engineering venture started by professionals having vast experience in Oil & Gas, Refinery, Chemical, Petrochemical, Fertilizer, Bio fuels, and Power Industry.

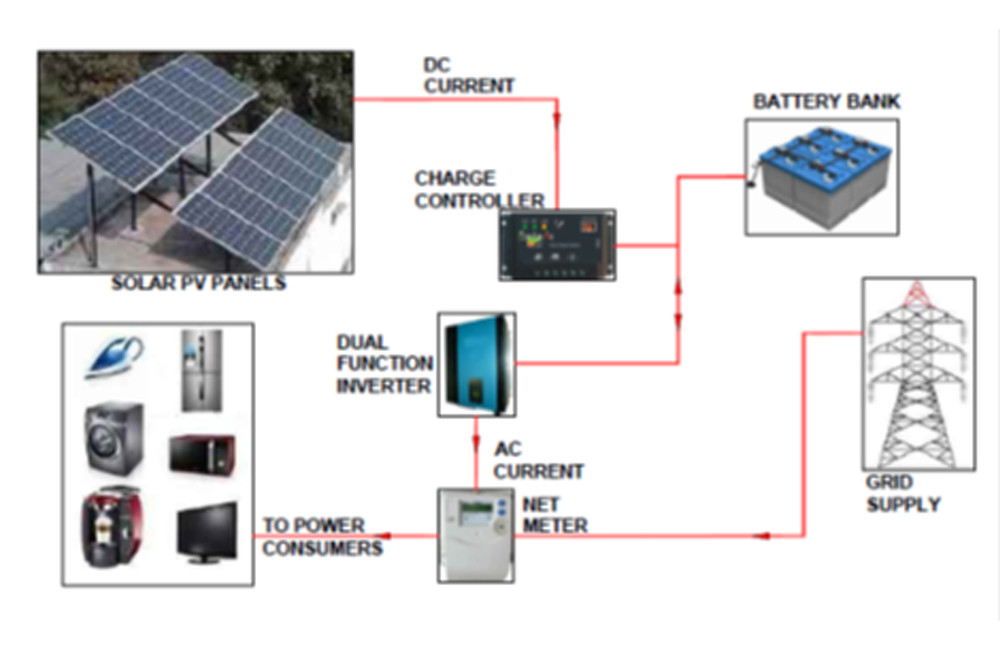

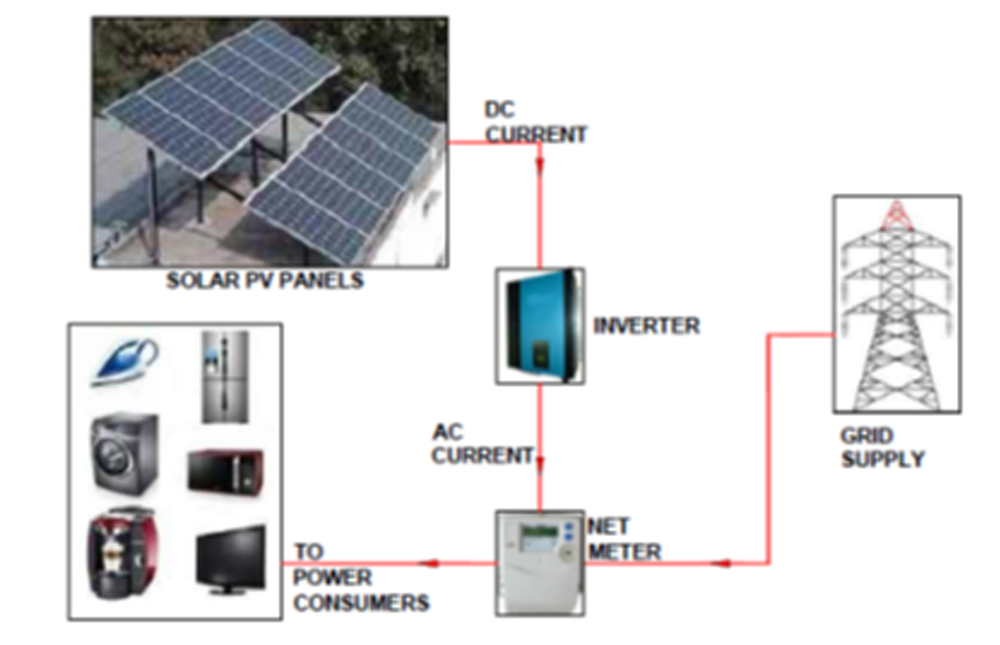

After completion of Twenty-Four + years of services in energy sector, the company Veeradutta Engineering Pvt. Ltd. has entered into Renewable Energy sector, the Solar Energy. The company is into Solar Power Generation models, i.e. off-grid and grid connected systems. We will execute the solar power project for prospective clients, either on the basis of Built-Transfer, or Built-Operate-Maintain-Transfer.

BACKGROUND

After completing Mechanical Engineering from College of Engineering,Pune (COEP), the company founder director, Mr. Prasad Pujari has worked more than Twenty-Three years in various multinational EPC companies, onshore/offshore design and inspection of piping in Oil & Gas and Petrochemical Plant. By experience of working in Japan, Muscat and Doha-Qatar at various positions in International Consultancy, he has knowledge of local and international standards related to Oil & Gas, Chemical, Petrochemical, Fertilizer and Power Industry.

The company will also benefit from Mr.Prasad Pujari’s experience as trainer in the field of API-570 certification training, ASME Codes, Piping Design, Valves, Pipe Flexibility Analysis etc. Refer to attachment for the ‘Certificate of Appreciation’ received from M/s. TUV Middle East for his past trainings executed.

Detail Engineering and Trouble Shooting Solutions

Detail Engineering and Trouble Shooting Solutions Detail Engineering and Trouble Shooting Solutions

Detail Engineering and Trouble Shooting Solutions Detail Engineering and Trouble Shooting Solutions

Detail Engineering and Trouble Shooting Solutions